Europe Drives Robot Innovation

There was a time when the world’s technological prowess was synonymous mostly with Silicon Valley. Be it for smartphones, coding, or data centers, the sun always seemed to shine on America’s tech corridors. But when it comes to the advancing realm of robotics—particularly humanoid robots—Europe has not just kept pace, but has actively jumped into the driver’s seat. Leading robotics companies, innovative startups, and forward-thinking research institutions are working tirelessly to make Europe a formidable force in shaping the future of this ever-evolving industry.

The Euro Touch: Europe’s Competitive Edge

Every region brings something distinct to the world of technology, and Europe is no exception. What sets Europe apart isn’t a sheer scale of venture capital flowing towards unicorn startups (because let’s face it, Silicon Valley still takes the win on that one)—instead, it’s the continent’s meticulous engineering, academic pride, and unwavering commitment to standards that shape its contribution to robotics.

Four pillars fuel Europe’s progress in robotics:

Scaling Up: Europe’s Robotics Powerhouses

One hardly needs to look far to spot Europe’s robotics crown jewels. Europe is home to an array of organizations that are shaping the way we think about robots—not just for industrial applications, but also for humanoid robots and service bots that can operate in daily life.

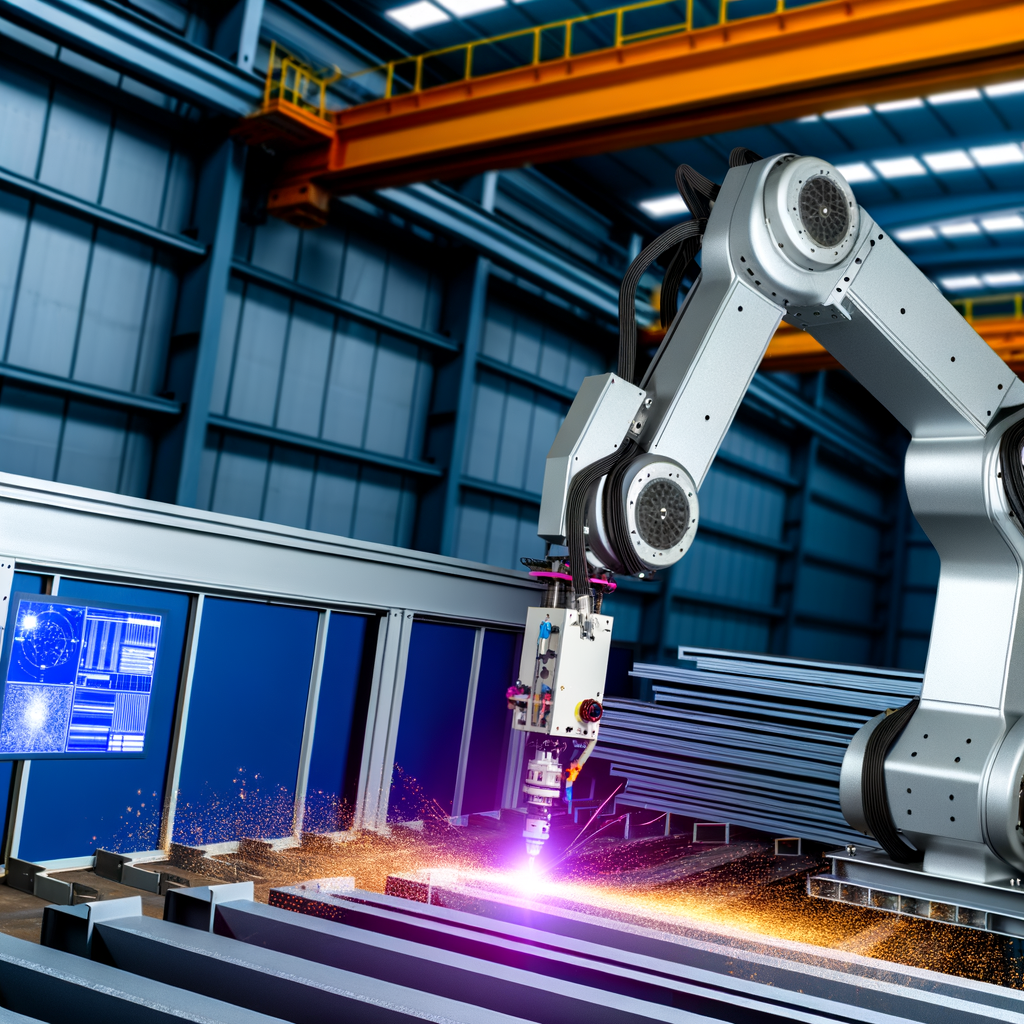

1. Germany: The Powerhouse

Germany remains the heart of European robotics, with an engineering lineage that predates the buzzword “innovation” itself. Companies like KUKA and Festo are heavily influential in driving forward the development of robotics.

Germany’s strength lies in its ability to merge high-quality mechanical engineering with precision robotics automation. In fact, KUKA, which is famous for industrial robots, is rapidly moving towards greater humanoid robot innovations, pushing boundaries for a future where robots serve equally on factory floors and households.

2. France: Focus on Service Robots

While Germany leads in manufacture and industrial robotics, France’s approach has uniquely focused on service robots. SoftBank Robotics Europe (formerly Aldebaran) created Pepper—arguably the world’s most commercially successful humanoid robot. French startups are zeroing in on robots that facilitate human-robot interaction, with eyes keenly set on elderly care, retail, and social settings.

France has put strong emphasis on AI-driven autonomy in robots (yes, I know I said I’d avoid that word, but bear with me!), enabling robots to better understand and respond to human needs.

3. Switzerland: Precision Robotics and Innovation

The picturesque country isn’t just famous for watches and high-quality chocolate. Switzerland’s robotics credentials are growing rapidly. With institutions like ETH Zurich, Switzerland is contributing heavily to creating robots that blend medicine, manufacturing precision, and humanoid features. From drones to robotic arms used in advanced surgeries, Switzerland is making the unimaginable real.

4. Scandinavia: Sustainable Robotics for Good

True to its nature-conscious ethos, the Nordic countries, especially Denmark and Sweden, are focusing on what is becoming an interesting hybrid: sustainable robotics. Companies like Denmark’s Blue Ocean Robotics tap into the need for robots that can assist industries such as healthcare while respecting the environment and focusing on ethical use.

Humanoids: Europe’s Next Big Leap

Humanoids might still evoke images of science fiction and robots mimicking humanoid behaviors, but Europe has a strong hand in turning the fiction into practical reality. With innovations such as eye-tracking robots, human-compliant actuators, and collaborative robots built to work seamlessly alongside humans, Europe is front and center stage in these advancements.

”Humanoids are not just a curiosity or a gimmick,” said Samuel Kunst, a robotics researcher based in Vienna. ”They play a role humans can’t sometimes fill.” Indeed, as humanoid robots develop more adaptive behaviors, they are becoming increasingly viable across a variety of industries, from helping out workers in hazardous environments to assisting in social care. They’re being designed to handle complexity whilst blending into everyday human environments.

European humanoid robot pioneers like PAL Robotics from Spain, and Robotdalen in Sweden, continue working towards increasingly human-like robots capable of performing both complex and routine tasks. If the idea of sharing a sidewalk with a humanoid feels surreal right now, give it a few years—the European humanoids might just beat Americans to the curb. Literally.

The Future of Robotics – Europe’s Place in the Puzzle

Despite all the significant progress, the road ahead remains filled with challenges. While Europe is making innovative strides in the field of robotics, it faces the challenge of scaling its startups efficiently to bridge the gap between academia to commercialization.

Multiple countries including Germany, France, Switzerland, and the Nordics are pooling resources to stay competitive in the rapidly evolving global market. Europe not only wants to lead but also ensure it stands guard over responsible, ethical, and sustainable robot development.

Nevertheless, one thing is increasingly evident—robots aren’t just the stuff of distant-future fantasies anymore. They are already being integrated into workplaces, hospitals, schools, and homes around the world. With its rich history in engineering and strong regulatory and ethical focus, Europe is ensuring that robots—whether industrial tools or humanoid companions—will shape a more efficient, safe, and exciting future.

As we continue down this incredible road of innovation, Europe’s contribution to the robotics revolution will only continue to grow. So, the next time you picture a futuristic robot by your side—or walking the streets—chances are high it might have “Made in Europe” embedded somewhere inside it.

—

In Conclusion: Europe’s unique strengths, from engineering brilliance to a robust ecosystem of collaboration and innovation, create its distinct edge in the global race for robot dominance. The next decade will see Europe play an even bigger part, possibly taking the lead in humanoid robotics, where humans and robots share a bond not just built on algorithms, but a harmonious and productive coexistence.